Material Processing Equipment

Small Footprint – Big Impact

The UniMelt® system is designed with production in mind. Modular and compact, it can be deployed with our partners at end-use locations or sources of raw materials. A 20’ x 20’ self-contained footprint of up to 100-200 tpa means easy and cost-effective deployment.

Core advantages:

- Continuous not batch: atmospheric pressure operation eliminates pump downtime

- Flexible environments: reducing, oxidizing, and neutral gas blends

- Contaminant-free thermal processing

- High throughput: up to 100-200 tons/year/unit (material dependent)

- Environmentally attractive: High yields, low waste generation

- Low OpEx: 99% microwave-to-plasma coupling efficiency, over double that of ICP plasma systems

- Flexible materials: metals, alloys, carbides, oxides, borides, nitrides…

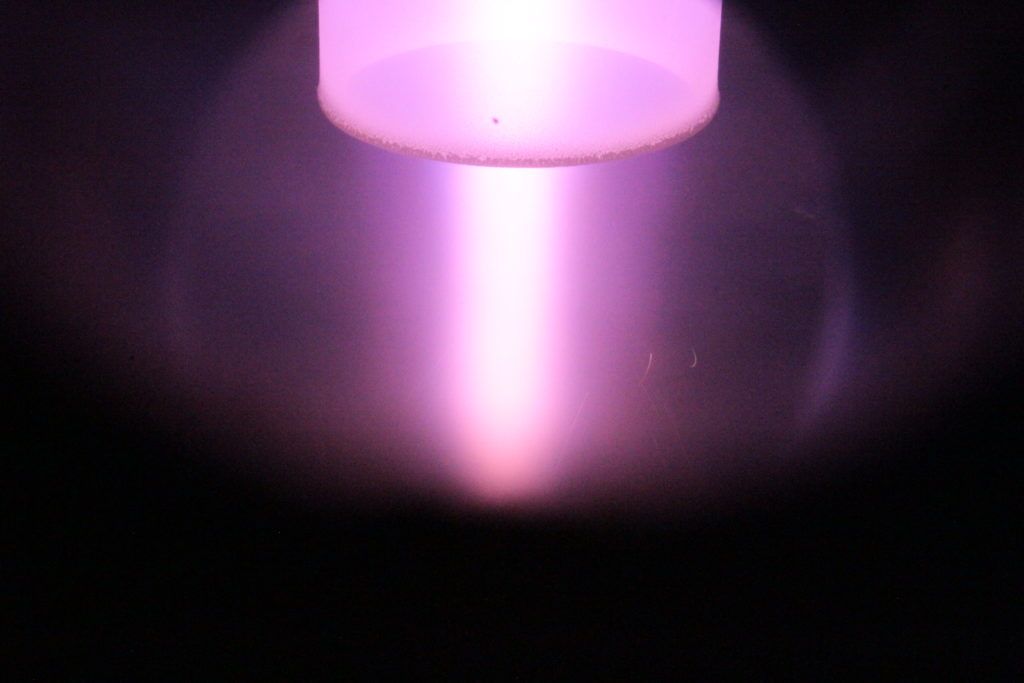

Reliable Microwave Plasma at the Core

6K produces the world’s only plasma system capable of high volume production of complex powders.

At the heart of the system is an atmospheric pressure microwave plasma generation unit that enables a large production zone with uniform temperature distribution, unmatched by arc-electrode or inductively-coupled plasmas.

The unit can operate up to powers as high as 120 kW to support volume production from a versatile range of feedstocks ranging from powders, liquid precursors, slurries, rod stock, and gas feeds.

By applying proprietary control algorithms to the unit, we can achieve precise and repeatable processing conditions.

Robust Production Equipment – Seamless & Efficient

UniMelt® systems are developed for production by veterans of the semiconductor & thermal processing industry who understand the requirements of manufacturing equipment.

6K’s equipment team is building systems for 6K’s production of powder products, its engineering services division, and to meet the needs of strategic partners.