Stainless Steel Metal Powder – SS316L

Stainless Steel Metal Powder for Additive Manufacturing

HIGH-QUALITY AND HIGH-PERFORMANCE STEEL METAL POWDERS

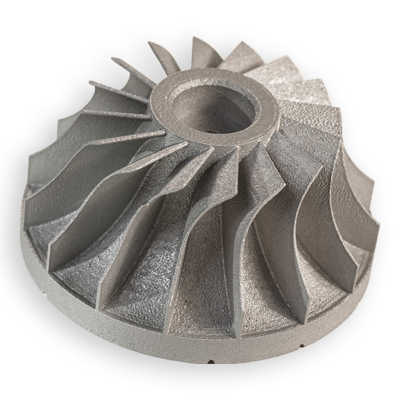

6K Additive SS316L stainless steel metal powder for additive manufacturing. SS316L metal powder is used in various AM manufacturing applications, including architecture and construction, automotive and transportation, industrial manufacturing, medical devices, laboratory equipment, and oil and gas. Designers in these fields can now take advantage of the design freedoms of additive manufacturing advanced applications and production methods. At 6K Additive we have a growing number of stainless steel metal powders available, starting with 316L to help meet the demands of cutting-edge additive manufacturing applications.

SS316L stainless steel metal powders produce additive manufactured parts that show a high level of corrosion resistance, toughness, and flexibility as well as a high resistance to acids. As a leading AM stainless steel metal powder vendor, we make our powders available in a variety of sizes, and we can customize the PSD that you are looking for.

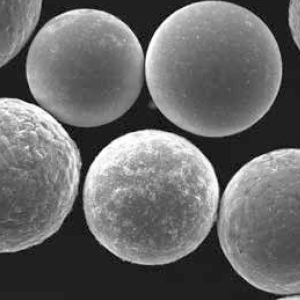

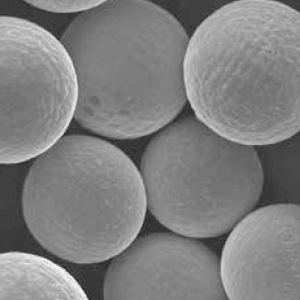

6K Additive stainless steels spherical powder – SS316L

Stainless Steel Powders from 6K Additive

6K’s UniMelt process delivers the highest yield in the industry for your target PSD and sustainably produces stainless steel powders that are:

Key Properties of Stainless Steel Metal Powders

SS316L stainless steel powder exhibits exceptional properties, making it a great option for additive manufacturing applications. Stainless steel possesses a high level of corrosion and oxidation resistance which safeguards the parts against corrosive elements and ensures their longevity and structural integrity even in oxygen-rich surroundings. Additionally, stainless steel powder demonstrates a high resistance to acids and performs well in elevated temperatures, making it reliable for applications involving high heat and exposure to acidic environments. The key properties of powdered SS316L stainless steel metal powder are:

Industries & Applications for Stainless Steel Metal Powders

SS316L metal powder used in additive manufactured parts is remarkable corrosion resistance, toughness, ductility, and acid resistance, ensuring their suitability for a wide range of applications. Some key industries that heavily rely on stainless steel powder for AM Manufacturing includes:

2022 AM Metal Market Analysis

6K Additive and SmarTech Analysis teamed up to look at the Future of the Metal Additive Powder Market with insights for scaling into the future.

Stainless Steel Metal Powder Specifications

| NOMINAL CHEMISTRY | |

|---|---|

| Iron | Balance |

| Chromium | 16.0 – 18.0% |

| Nickel | 10.0 – 14.0% |

| Molybdenum | 2.00 – 3.00% |

| Manganese | 2.00% (Max) |

| Silicon | 1.00% (Max) |

| Carbon | 0.030% (Max) |

| Phosphorous | 0.045% (Max) |

| Sulfur | 0.030% (Max) |

| PHYSICAL PROPERTIES | (typical) |

|---|---|

| 15-45 μm | |

| Apparent Density | 4.5 G/CM3 |

| Tap Density | 4.9 G/CM3 |

| Hall Flow | 22 s/50g |

| TENSILE PROPERTIES – SS316L | YS (MPa) | UTS (MPa) | EL (%) | RA (%) |

|---|---|---|---|---|

| 6K Additive* XY | 313 | 602 | 51 | 66 |

| ASTM F3184* XY | 205 | 515 | 30 | 30 |

| 6K Additive* Z | 307 | 573 | 61 | 66 |

| ASTM F3184* Z | 205 | 515 | 30 | 30 |

- Annealed

EXPORT CONTROLLED

Products, technical data, technology and services of 6K Additive Products are subject to U.S. export controls under the Export Administration Regulations and the International Traffic in Arms Regulations. Products, data and technology may not be resold, diverted, transferred, transshipped, made available to a foreign national within the United States, or otherwise disposed of in any other country outside of its intended destination, either in its original form or after being incorporated into other products or data without the prior written approval of 6K Additive. In addition, products, data and technology may not be exported or re-exported to entities or persons that are ineligible under U.S. law to receive U.S. products and technology.