Angular Metal Powder Production

6K Additive proprietary technology allows us to produce superior metal powder for demanding applications

Proprietary manufacturing process producing highest quality metal powder

We specialize in sizing and metal upcycling to produce high-purity and high-quality metal powders

Titanium (Ti)

Chromium (Cr)

Applications for Angular Powders

Producing the highest quality metal powders for the most demanding applications

6K Additive’s proprietary manufacturing process produces angular powders that can withstand the industry’s most demanding applications. Our proprietary services include crushing, milling and sizing, material sourcing, and recycling. Contact us today to learn more.

Coatings such as cold spray, HVOF, and flame spray are used in aerospace, medical energy, and other industrial applications.

Angular powder used to make parts for use in the electrical market for vacuum interrupters.

MIM is used to produce intricate metal parts for biomedical, automotive, firearms, and consumer goods applications.

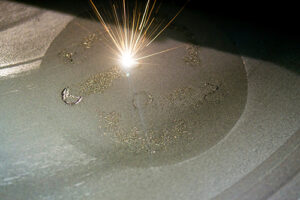

Angular powder can be used in many forms of additive manufacturing as primary powder or mixed with spherical powder.

Angular powder used for sputtering targets in the manufacturing of semiconductors, hard drives, and solar panels.

Angular titanium powder is used in pyrotechnics to produce bright white sparks of a superior quality.

Metal parts and components used in the harshest environments deliver optimal performance if they are made with the highest quality powders. Contact us today to learn more.

High Performance Powders Backed by Stringent Quality Control

High Quality Metal Powders at Production Scale

6K Additive’s quality control and manufacturing process produces the highest quality metal powders consistently, with the highest purity in the industry.

Comprehensive Powder Test & QC

Rigorous quality control with extensive in-house analytical capabilities including micro-CT, gas analysis, ICP, XRD, SEM and EDS.

Powder Production & Testing

ISO certified facility qualified to produce metal powders for the most challenging high-performance markets such as aerospace and defense and energy. Meeting or exceeding ASTM and ASM standards verified by leading industry experts, partners, and customers.

Powder Tracking & Preparation

Industry-standard methods for powder blending, lot control and packaging. Powder traceability plays a critical role in ensuring product quality and safety.

Want to Learn More About Our Metal Powders?

EXPORT CONTROLLED

Products, technical data, technology and services of 6K Additive Products are subject to U.S. export controls under the Export Administration Regulations and the International Traffic in Arms Regulations. Products, data and technology may not be resold, diverted, transferred, transshipped, made available to a foreign national within the United States, or otherwise disposed of in any other country outside of its intended destination, either in its original form or after being incorporated into other products or data without the prior written approval of 6K Additive. In addition, products, data and technology may not be exported or re-exported to entities or persons that are ineligible under U.S. law to receive U.S. products and technology.